close

Choose Your Site

Global

Social Media

Views: 0 Author: Tiana Publish Time: 2025-09-15 Origin: Site

In the LED lighting industry, heat dissipation has always been a critical factor that directly affects product performance and service life. As LED power levels continue to rise, excessive heat accumulation around the chip and driver can accelerate light decay, shorten lifespan, and compromise lighting quality.

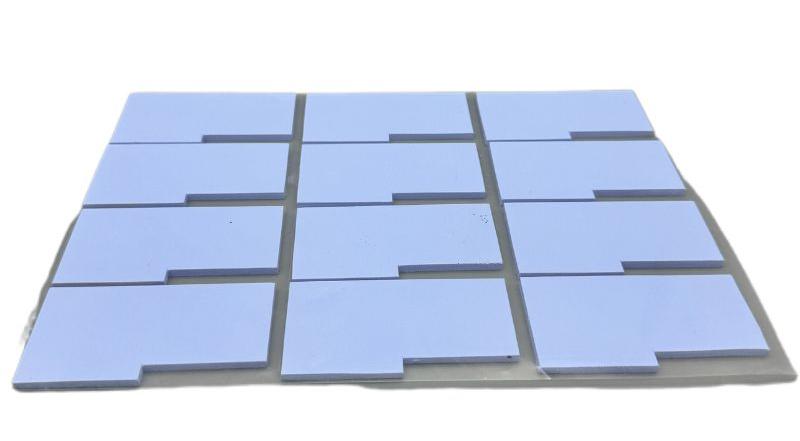

Thermal pads, as an advanced thermal management material, provide an ideal solution for LED lighting applications thanks to their excellent thermal conductivity and electrical insulation.

Key Advantages:

High Thermal Conductivity: Ranging from 1.0 to 15.0 W/m·K, thermal pads quickly transfer heat to heat sinks, effectively lowering LED junction temperature.

Soft and Conformable: With great compressibility, they fill microscopic air gaps in LED assemblies, reducing thermal resistance.

Electrical Insulation: Ensures both efficient heat dissipation and system safety.

Easy Application: Can be cut to fit different LED lighting designs, making installation simple and efficient.

Typical Applications:

LED bulbs, spotlights, and panel lights

Outdoor street lights, tunnel lights, and landscape lighting

LED display panels and high-power illumination systems

By integrating thermal pads, LED lighting products can significantly reduce junction temperature, stabilize brightness, and extend overall lifespan—helping manufacturers enhance product reliability and market competitiveness.

2025.09.15